Processing

HEAT-TREATMENT

The raw material undergoes through a heat-treatment process (hot and cold) developed by CerealVeneta, specifically settled for the function that the semi-finished product must perform in the customer’s finished product.

The product undergoes to a dry heat treatment with moisture extraction, which reduces the bacterial load and stabilizes the enzymatic part using low temperatures. The peculiarity of the CerealVeneta process allows not to degrade the nutritional properties of the raw material and at the same time to avoid subsequent degradation and oxidation phenomena, with better perfomance in the final product.

If the customer’s request provides for an improvement not only of the nutritional properties but also of the organoleptic ones, the raw material undergoes through a greater heat treatment which, depending on the set process parameters, allows to modify color, aroma, taste and also the structure of starches, obtaining a semi-finished product with a higher resistant starch content or with improved binding activity.

The raw material is subjected to a pre-cooking process, with subsequent decanting, lamination and drying. Based on the specific need, the applied process allows to obtain a different bostwick degree of starch pre-cooking, to meet the customer’s plant requirements.

PHYSICAL CONDITIONING

The raw materials, native or heat-treated, follow processes suitable for their physical conditioning, with one or multiple passages in line. The whole raw material undergoes physically conditioning and comes out in a different format and dimension depending from the process used and the engine setting.

CerealVeneta’s crushing process makes use of ruled rolling mills and in-line roller mills, which condition the raw material bringing it to the particle size necessary to be used in the process.

Starting from a whole raw material or previously conditioned by crushing, the rolling process, thanks to smooth roller mills, allows to get an almost “definitive” semifinished product in terms of shape and size. The format obtained varies from a “leaf” to a granular product, depending on the raw material and the pre-treatment it has undergone.

If the application purpose of the semi-finished product does not require transformation into flour, but at the same time requires granulometric uniformity or the absence of dust, the physically conditioned raw material undergoes through the calibration or sieving phase. Through a series of sieves, the product is carefully selected, obtaining a product with a degree of particle size purity suitable for the customer’s request.

MILLING

Along the production process in CerealVeneta, the grain or seed enters the crucial phase of transformation, which leads the selected raw material, cleaned and conditioned, to take on those physical characteristics necessary to fulfill their function in the finished product, without compromising the functional and organoleptic characteristics.

This process has been developed and perfected over the years by CerealVeneta and is called «Cryo-milling». Through the use of special cold mills, the raw material, whether native or heat-treated, is milled to variable grain sizes, depending on the specific request. The use of the cold in the milling process allows to preserve the organoleptic characteristics of the product, it also helps to reduce the bacterial load and create less mechanical stress, one of the main factors responsible for the development of oxidative phenomena.

If the application functions require an very thin semi-finished product, it is possible to process the raw material at particle sizes below 300 mcr. Also in this case are used cold temperatures, hence the name of the process “cryo-milling”. Thanks to this very fine milling, the technological and organoleptic qualities of the semifinished product are improved, as well as the ability to bind and structure the product (especially in pulses).

To obtain a further degree of customization, semifinished products of different origin, format and size, can be mixed in dedicated systems that make the recipe components homogeneous, and that allow the supply in bags, big-bags, or tanks.

PACKAGING

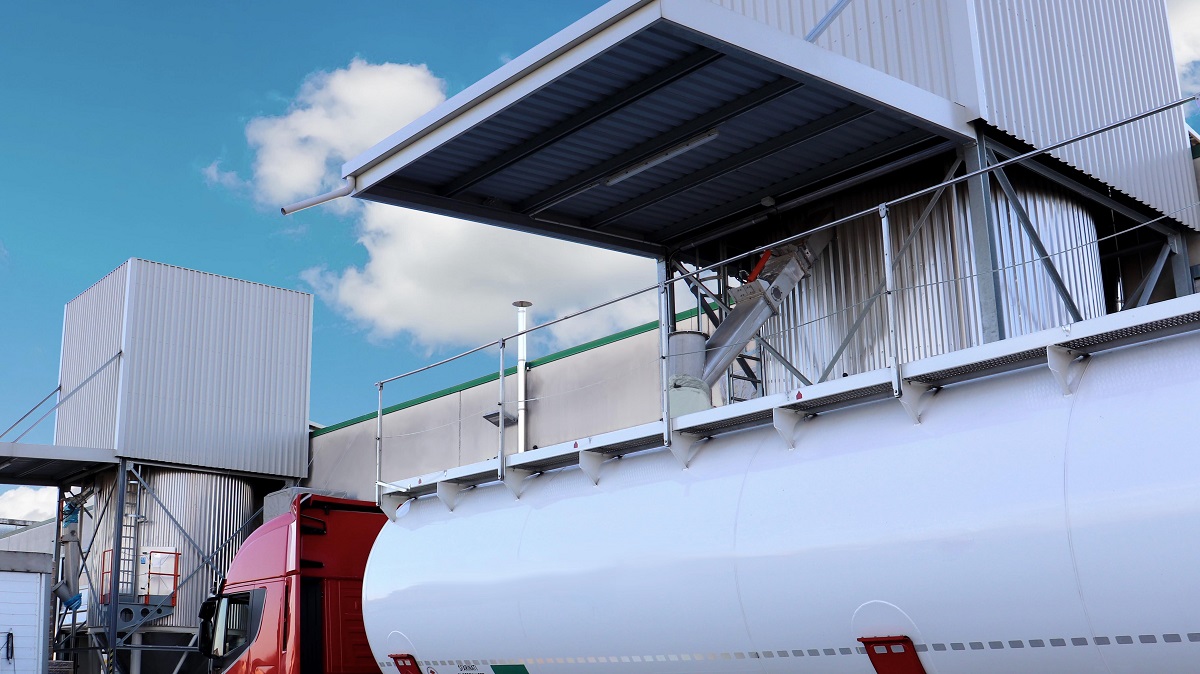

Once the processes for the making of the semi-finished product have been completed, the product is ready to be packaged. Depending from the request or reasons related to the nature of the semi-finished product, there are different solutions.

The semi-finished product can be shipped in a food tank, in big bags or in bags. For the last two kind of packaging, in addition to transport by standard truck, it can be provided also insulated trucks or at controlled temperatures (+ 4 ° / + 7 °). This method is applied from April to September, especially for semi-finished products derived from oil seeds or from raw materials with a high fat content.

The semifinished product, through thermal conditioning during the packaging phase, is packed at temperatures lower than the ambient temperature after undergoing the heat treatment process.

It is also possible to package the semifinished product with vacuum systems applied to containers in which big bags and paper bags are placed.